ISO 14001 Certification

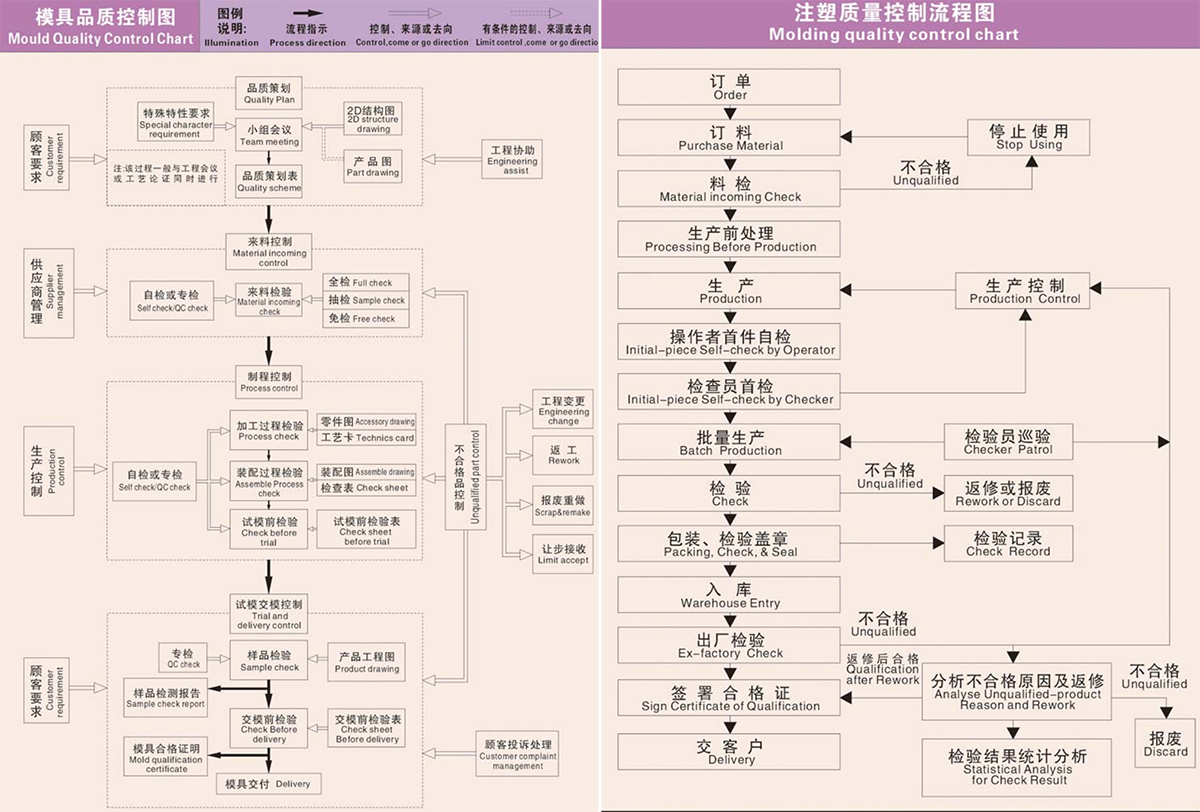

Z-Top Solution is the extension of Z-Top Group subsidiary, mainly for major companies for internal and abroad, to provide plastic injection mold processing related services. Give customer supporting and provide mold solutions, to build a set of injection mold manufacturing, and surface treatment. Assembly one of the specialized production enterprise. In the injection mold industry, try to become the leading enterprises.

Shenzhen Z-Top Special Steel Co., Ltd. was founded in 1990, it’s a first company of Z-Top Group. The mainly business is mold steel, metal machinery. The company specializes in mold steel mainly engaged in the project, but also equipped with heat treatment processing.

Large and medium moulds up to maximum weight 40T, and size is 2500*1600*1800 (MM)

Precision Moulds making The minimum tight tolerance of machining is ±0.003 - 0.005 mm.

We have strong engineering team including:

senior project engineer 10

senior mould designer 15

CNC programming 10

quality engineer 5

product engineer 5

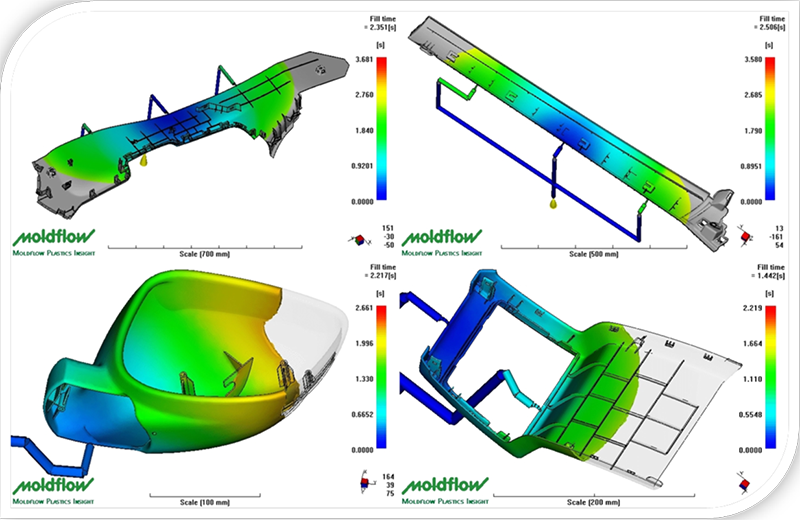

We have a batch of skilled designers who are proficient in the design software such as UG, Pro-E, Moldflow etc.. We can exactly express the design purpose of our customer from design idea to the form of products concept, then to one time molding of metaphase construction assembly.

With the advanced CAD/CAM/CAE software, we collaborate closely with our customers on all aspects of the programs, so as to develop the best designed molds that are easy to maintain and plastic components that are cost-effective to produce.

Z-TOP is dedicated to the establishment and preservation of a close, on goingcustomer-vendor relationship based on honesty, quality, reliability and service.

Our customers range from the small startup company to large multinational corporations which demonstrates our range of capabilities, services and most of all, our attitude. We would welcome the opportunity to solve your most challenging plastic injection molding production requirements also.